INDUSTRIAL IMAGING

INDUSTRIAL IMAGING

The manufacturing industry faces increased challenges in delivering products of the highest quality in the shortest time at competitive prices. As the dimensions or crucial features of products and parts become smaller, reaching down to the micrometer range, the effort and connected costs to characterize and evaluate product properties are increasing dramatically.

In particular, for the characterization/inspection of complex geometries or critical features located inside the materials, non-destructive imaging technologies and evaluation methods are of great advantage. Unfortunately, conventional solutions are either very costly and/or rather slow (e.g., X-ray computer tomography,) or they do not fulfill the requirements (e.g., standard ultrasound) for advanced applications such as high-resolution inspection of microparts.

In particular, for the characterization/inspection of complex geometries or critical features located inside the materials, non-destructive imaging technologies and evaluation methods are of great advantage. Unfortunately, conventional solutions are either very costly and/or rather slow (e.g., X-ray computer tomography,) or they do not fulfill the requirements (e.g., standard ultrasound) for advanced applications such as high-resolution inspection of microparts.

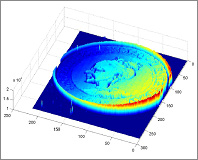

However, a state-of-the-art solution exists that meets these demands -- high resolution, high-speed imaging based on Optical Frequency Domain Reflectometry (e.g., Optical Coherence Tomography) and Chromatic Confocal Microscopy for industrial profiling. Laser sources play a key role in these solutions, and Micron Optics' performance leading swept laser sources in the 1.06 µm, 1.3 µm and 1.5 µm spectral ranges can be custom built to meet the demands of applications in industrial imaging where resolution, high speed and cost are key parameters.

However, a state-of-the-art solution exists that meets these demands -- high resolution, high-speed imaging based on Optical Frequency Domain Reflectometry (e.g., Optical Coherence Tomography) and Chromatic Confocal Microscopy for industrial profiling. Laser sources play a key role in these solutions, and Micron Optics' performance leading swept laser sources in the 1.06 µm, 1.3 µm and 1.5 µm spectral ranges can be custom built to meet the demands of applications in industrial imaging where resolution, high speed and cost are key parameters.

Visit the Document Library to read more about these and other Industrial Imaging applications.

- Press Release

March 30, 2012 -- Micron Optics expands global sales and system integrator network - Press Release

February 29, 2012-- Micron Optics expands product & technology team - In the News

New Device Saves Vision Before Glaucoma Hits - Upcoming Event

Photonics West 2013

February 5-7, 2013

San Francisco, CA, USA - More News & Events