TECHNICAL SUMMARY

TECHNICAL SUMMARY

![]() Micron Optics is proud of its technology, having over 28 patents covering core components, instruments and sensors as well as additional intellectual property generated each year. Products labeled "Micron Optics Tuned" use the company's core technology and benefit from its rigorous qualification, consistent manufacturing, and high quality standards. These products are "tuned" to peak performance.

Micron Optics is proud of its technology, having over 28 patents covering core components, instruments and sensors as well as additional intellectual property generated each year. Products labeled "Micron Optics Tuned" use the company's core technology and benefit from its rigorous qualification, consistent manufacturing, and high quality standards. These products are "tuned" to peak performance.

Sensing Instrument Technology

In the mid 1990's, as the first Fiber Bragg Gratings (FBGs) were being tested for sensing applications, Micron Optics realized that its core technology would play an important role. Specifically, the Micron Optics Fiber Fabry-Perot Tunable Filter technology (FFP-TF) was recognized as an ideal match for sensor measurement applications.

The early FBG sensor measurement instruments, or "interrogators" as they came to be known, used the FFP-TF's narrow passband shape to scan the reflected optical spectrum in front of a photodetector. In this architecture, broadband light is launched down the fiber and spatially distributed FBGs reflect light, each at their own unique wavelength. The scanning FFP-TF based interrogator then determines the precise wavelength of each FBG reflection and this information is then used to calculate the measured strain or temperature.

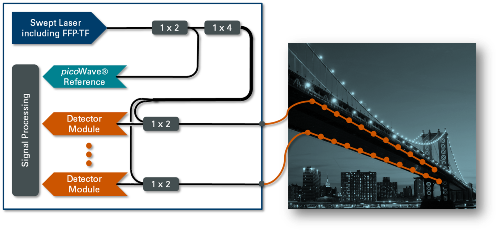

Today, the FFP-TF is still an essential element of the Micron Optics sensing instruments optical engine, but now the tunable filter serves as the key component in our "swept" lasers. Using a swept laser source instead of a broadband source yields many advantages:

- High power - greater distances to sensors (10s of kilometers) and allows multi channel functionality (64)

- Wide tuning range - up to 16 times more sensors per fiber (>100/fiber)

- Narrow source - better repeatability and accuracy (sub-picometer)

- Fast laser scanning - dynamic measurements (KHz)

- Built-in Calibration - no periodic recalibration required (ever)

- Rugged design and construction

No other technology exceeds the combination of speed, accuracy, and sensor capacity of Micron Optics' sensing instruments. In fact, many interrogators manufactured by other companies around the world use the Micron Optics FFP-TF as the core components of their optical engine. There are more Micron Optics-based interrogators installed and operating around the world today than any other type. Many of these installations have been in continuous operation since the first units were shipped in the late 1990s.

Micron Optics has collaborated with the National Institute of Standards and Technology (NIST) in the USA to document clear definitions of performance criteria for our interrogators. Accuracy, repeatability, stability, etc. are all defined in detail, and our performance instrument performance is validated by NIST-endorsed procedures. Detailed test documentation is available for all instrumentation products that outlines the methods used for qualification and shows the results of the applicable qualification tests for CE, FCC, and FDA. No other manufacturer of fiber optic sensing interrogators has such a rigorous, NIST-traceable, qualification procedure.

FBG Sensor Technology

The intrinsic measurement advantages of optical fiber sensors have led the way in the development of rugged and reliable sensor packaging designs, enabling simple, safe handling of the sensor components. These development efforts were initiated at Micron Optics following a thorough survey of commercially available optical strain sensors on the market.

The intrinsic measurement advantages of optical fiber sensors have led the way in the development of rugged and reliable sensor packaging designs, enabling simple, safe handling of the sensor components. These development efforts were initiated at Micron Optics following a thorough survey of commercially available optical strain sensors on the market.

In 2004 Micron Optics gathered packaged FBG strain gages from 12 sources. None performed well in harsh environments. Few exhibited consistent behavior from gage to gage. Since that time, Micron Optics has adopted a set of calibration and test procedures commonly used in the electrical strain gage market to develop and validate performance on a complete line of consistent and reliable optical strain gages and temperature probes.

To ensure long-term stability of its designs, Micron Optics sensors use neither epoxies nor other glues as part of the assembly process. As a result, these optical sensor designs yield steady, consistent measurement results over a variety of environmental conditions, while minimizing the sensitivity of installation variations from sensor to sensor.

Micron Optics sensors are tested to a combination of ASTM and Telecordia requirements. In addition, they are tested against all applicable metrics for temperature, humidity, fatigue and vibration conditions. Through this intensive qualification process, Micron Optics ensures reliable operation over the lifetime of its sensor products.

Micron Optics' commitment to thoughtful design and rigorous qualification yields gages that are easy to install and use, are uniformly qualified, and are all consistent in performance. Many versions are available in armored packages for installation in harsh application environments (e.g., embedding in concrete). Micron Optics' innovative substrate designs and anchoring technologies, in combination with its rigorous manufacturing and testing procedures, yield a series of optical sensors that are uniquely qualified to be branded "Micron Optics Tuned".

Sensing Analysis Software

Optical sensors and interrogators offer many unique measurement advantages, as compared to conventional electrical sensors. Historically, integration of an optical measurement system required not only judicious selection of sensors and measurement systems, but also an extensive software development effort by the end user to pull the components functionally together. Micron Optics has developed its ENLIGHT software package to ease the integration of the optical sensor system and facilitate many of the common features needed in such measurement systems.

Optical sensor systems share many operational characteristics with conventional electronic sensors systems. Concepts such as sensor limits and alarm conditions, for example, apply equally well to both types of systems and are thus well supported by software for either sensor class. Optical sensors have some additional special properties not represented in conventional electrical sensor technologies and require software management and control. Optical spectrum provisioning and spectral peak detection are two examples of such properties. Micron Optics ENLIGHT endeavors to combine the traditionally useful features of conventional sensor software with the specific needs of the optical sensor system to create a single software tool for the optical sensor system integrator.

Optical sensor systems share many operational characteristics with conventional electronic sensors systems. Concepts such as sensor limits and alarm conditions, for example, apply equally well to both types of systems and are thus well supported by software for either sensor class. Optical sensors have some additional special properties not represented in conventional electrical sensor technologies and require software management and control. Optical spectrum provisioning and spectral peak detection are two examples of such properties. Micron Optics ENLIGHT endeavors to combine the traditionally useful features of conventional sensor software with the specific needs of the optical sensor system to create a single software tool for the optical sensor system integrator.

Complete Solutions

The combination of Micron Optics field proven interrogators, qualified sensors, and ENLIGHT software provides all of the fundamental tools required to address scores of applications in dozens of application fields. FBG technology in general, and Micron Optics tools specifically, are so flexible that they can be used to address application needs across a diverse range of fields, from bridges to oil wells to medical devices. In addition to its standard product offerings, Micron Optics also designs and manufactures custom interrogation modules, sensors, and software to meet targeted performance and price goals for volume applications. Contact Micron Optics to learn more.

- Press Release

May 17, 2012 --Micron Optics releases ENLIGHT 1.5 Optical Sensing Software - Press Release

April 30, 2012 -- Post-Tensioned Tendon Monitoring on the Robert E. Ginna Nuclear Containment Structure - Press Release

March 30, 2012 -- Micron Optics expands global sales and system integrator network - Press Release

February 29, 2012-- Micron Optics expands product & technology team- Press Release

September 1, 2011 -- Micron Optics releases new 2MHz optical sensing module, the sm690- Product Release

July 29, 2011 -- Micron Optics releases new displacement gage, the os5100- Press Release

June 28, 2011 -- Micron Optics Optical Monitoring System Installed on Mount Rushmore- More News & Events

- Press Release